Tare da babban ma'auni daidai, saurin amsawa mai sauri, ƙarfin hana tsangwama, nau'in WLX-II mai ci gaba da auna kayan aikin zafin jiki na ƙarfe na ƙarfe yana da ainihin lokacin sa ido kan narkakken ƙarfe na zafin jiki, wanda shine sabon ƙarni na ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙarfe zafin ma'aunin ƙarfe. samfur.Ta aikace-aikace a cikin shuke-shuken karfe daban-daban, an tabbatar da aminci da kwanciyar hankali na samfurin.Tabbas shine samfurin da ya dace don maye gurbin platinum rhodium thermocouple thermodetector.

Ma'auni: 700-1650 ℃

Rashin tabbas na auna: ≤ ± 3℃

Rayuwar bututun zafin jiki: ≥24 hours (ana iya samar da bututun zazzabi na rayuwa daban-daban bisa ga yanayin wurin)

Zazzabi mai amfani: 0-70 ℃ (ganewa), 5-70 ℃ (siginar processor)

Daidaitaccen fitarwa: 4-20mA/1-5V (daidai da 1450-1650 ℃)

Ƙarfin da ake fitarwa: ≤400Ω(4-20mA)

Daidaiton fitarwa: 0.5

Wutar lantarki: Ac220V± 10V, 50HZ

Ikon: Mai sarrafa siginar 30W da babban nunin allo 25W.

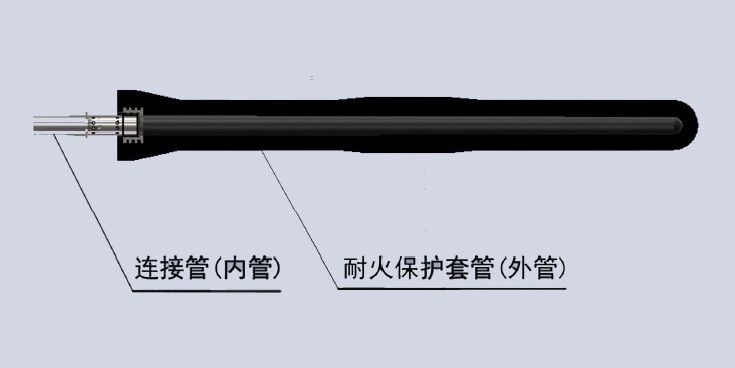

Bututun zafin jiki ya ƙunshi bututu mai haɗawa da kwandon kariya mai jure wuta.Rubutun kariyar da ke jure wuta yana da alaƙa da mai ganowa ta bututu mai haɗawa.Dangane da zurfin zurfin tundish narkakken karfe da lalata narkakken ƙarfe zuwa bututun zafin jiki, tsawon zafin jiki yana da ƙayyadaddun bayanai na 1100mm, 1000mm da 850mm;diamita yana da ƙayyadaddun bayanai na ¢85mm da ¢90mm, waɗanda za a iya keɓance su bisa ga buƙatun masu amfani.

Ana saka bututun zafin jiki kai tsaye a cikin narkakkar karfe don fahimtar zafin jiki;Ana buƙatar zurfin shigarwa zuwa ƙasa da 280mm.Siginar auna zafin jiki yana daga gefen ciki na kasan bututu na waje;lokacin mayar da martani na kayan aiki daidai yake da lokacin makamashi mai watsawa daga gefen waje na bututun zafin jiki zuwa gefen ciki.Ana amfani da bututu mai haɗawa don haɗi tsakanin bututun zafin jiki da mai ganowa.Bututun ciki shine yafi kawar da hayaki a cikin bututu da tabbatar da tsabtar hanyar haske.

| Abu | Jiki | Aluminum-magnesium-carbon slag line | Magnesium slag line |

| Al2O3% | 54.8-56.2 | 61.7-62.2 | 22.7-23.3 |

| SiO2% | 7.0-8.0 | ||

| ZrO2% | |||

| MgO% | 8.5-9.0 | 41.4-42.0 | |

| FC% | 27.1-27.9 | 25.0-25.4 | 29.2-30.0 |

| Girman girman g/cmз | 2.46-2.53 | 2.71-2.79 | 2.48-2.52 |

| Bayyanar porosity% | 11.5-14.8 | 11.4-13.8 | 11.8-12.8 |

| Ƙarfin murkushe sanyi MPa | 20.9-32.9 | 21.2-27.6 | 20.7-26.7 |

| Ƙarfin sassauƙa a yanayin zafi na al'ada MPa | 20.9-32.9 | 5.4-7.3 | 5.5-8.3 |

Mai ganowa ya ƙunshi abubuwan gani na gani, mai canza hoto na hoto, layin watsa siginar, filogi fitarwa da bututun iska mai sanyaya, da dai sauransu. Matsakaicin shigar da mai ganowa yana haɗawa da bututu mai haɗawa na bututun zafin jiki;tashar fitarwa ta haɗa tare da mai sarrafa siginar ta hanyar toshe 6P;Ana haɗa tashoshi masu shigarwa da fitarwa ta hanyar layin watsa sigina wanda aka kiyaye ta hanyar bututun iska mai sassauƙa.Na'urar gani tana watsa siginar infrared da aka aika daga kasan bututun zafin jiki zuwa mai canza wutar lantarki, sannan mai canza wutar lantarki ya canza siginar gani zuwa siginar lantarki sannan ya tura shi zuwa na'urar sarrafa siginar ta hanyar layin watsa sigina.

Mai sarrafa siginar ya ƙunshi ƙarfin wutar lantarki, tsarin sarrafa siginar analog, tsarin jujjuyawar analog-dijital, tsarin sarrafa dijital, tsarin sadarwa da ƙirar nuni, da dai sauransu. Babban nunin allo ya ƙunshi tsarin wutar lantarki, tsarin sadarwa da ƙirar nuni, da sauransu.

Mai sarrafa siginar yana da aikin diyya sau biyu na zafin jiki, wanda zai iya yin ramawa ta atomatik zuwa karkacewar auna sakamakon zafin yanayi na firikwensin da zafin aiki na kayan aiki.

Mai sarrafa siginar yana karɓar shigarwar siginar lantarki ta mai ganowa;Ana ƙididdige yawan zafin jiki na narkakken ƙarfe ta microprocessor bisa ga ka'idar radiation infrared kuma ana nunawa akan allon.A halin yanzu, ana iya nuna bayanan zafin jiki na ainihi akan babban allo ta hanyar aikin sadarwa.Ana iya fitar da siginar lantarki zuwa babbar kwamfuta mai sarrafawa don sa ido kan aiwatar da aikin simintin gyare-gyare na lokaci.

1) Ta amfani da wannan samfurin, za mu iya ci gaba da kuma daidai gane zafin jiki na tundish narkakkar karfe da kuma bambancin Trend, daukan matakai a cikin lokaci don hana zubar jini-fita ko ruwa bututun ƙarfe toshe saboda mafi girma ko ƙananan zafin jiki na narkakken karfe, rage asara saboda zubar jini. -fita da daskararre ramuka, da lokacin zaman banza saboda hatsarori, don haka haɓaka ƙimar aikin injin ɗin.

2) Ta amfani da wannan samfurin, za mu iya sanin canjin canjin yanayin zafin karfe na tundish.Bisa ga wannan ƙa'idar canjin, za mu iya gabatar da ƙarin buƙatun ma'aunin fasaha zuwa tsari na gaba, kamar ƙera ƙarfe da tacewa.Ta yin wannan, ba za mu iya kawai rage tapping zafin jiki da 15 zuwa 20 ℃, amma kuma tabbatar da m tsari tsarin, ƙara management matakin da zafin jiki auna daidaito.

3) Tare da ma'aunin zafin jiki daidai, wannan tsarin zai iya rage digiri na superheat ta 5 zuwa 10 ℃.Ta hanyar rage darajar superheat za mu iya samun yanki mai faɗi daidaitaccen yanki, sauƙaƙe rarrabuwar simintin simintin, yadda ya kamata ku guje wa lahani na sako-sako, raguwar rami da fasa, da haɓaka ingancin ƙarfe;A halin yanzu, ta hanyar rage darajar superheat za mu iya ƙara saurin simintin ƙarfe da ingancin ƙarfe.Ayyukan aikace-aikacen sun tabbatar da wannan tsarin auna zafin jiki na iya ƙara saurin simintin gyare-gyare da kashi 10% akan matsakaita.